Machine Shop Saw Operationthe Mechanic

- For over 25 years Vectrax has been meeting the toughest challenges of modern machining. Designed from the castings up, these value packed machines are built to exacting industry standards and include high performance features you would only expect from top tier industry brands.

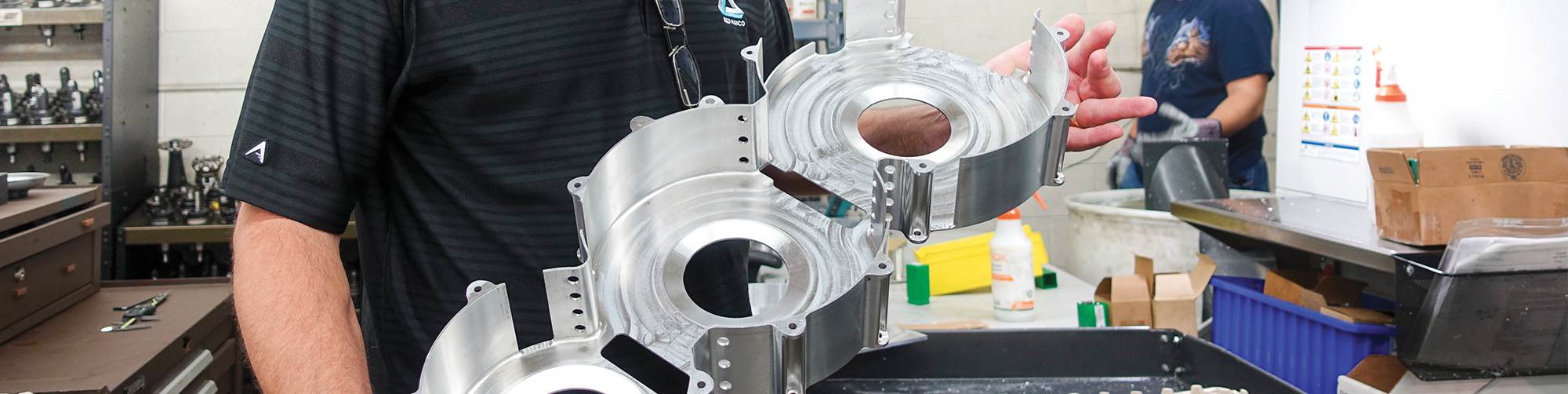

- Machine Tool Rebuilding and Repair. Both CNC and Conventional Machining. Sheet Metal Work. Fabrication and Welding. Waterjet Cutting. New Machine Sales and Service. Used Equipment Sales. Carbide Cutter Blades Product Line. Metal Recycling Blade Product Line. Facility Includes: 12,000 sq. Of warehouse and shop area.

Machine Shop Tools & Equipment. Penn Tool Co is pleased to carry a wide selection of machine shop tools and equipment.Our machine tools for sale are comprised of a variety of different products that are used to shape, cut, grind, shear, form, and basically shape metal into a desired part. Feb 5, 2020 - Explore mark brown's board 'Machine tools', followed by 124 people on Pinterest. See more ideas about machine tools, machine shop, metal working.

Maximize Machine Uptime & Production Efficiency for Greater Profitability

In today's fast-paced manufacturing environment, machine uptime is critical. That's why we support job shops, OEM's and businesses large and small alike with expert machine tool services.

With a strong support team standing behind you and expert applications engineers working together with your technicians to optimize your workflow, we can keep your machine tools running at maximum efficiency and your business performing at maximum profitability. Contact us today to learn more about our machine tool repair services.

Our Service Technicians are factory trained by the machine tool manufacturers we represent, like TRUMPF, Standard Industrial and others, on all aspects of maintenance, calibration and repair. In addition, we work on many other brands and machine types, from the latest CNC cutting, punching and robotic systems to traditional metal working equipment. Best of all, our application engineering team is trained to help solve complex problems, identify efficiencies, and help optimize your production processes, equipment and tooling for maximum success.

So if you're interested in learning more or placing an order for service, parts or tooling, click below. One of our team members will be in touch to answer all of your questions and schedule a visit. We look forward to helping your shop perform at its best!

The Sawing Machine Operator sets up, operate, or tend wood sawing machines, which includes head sawyers.

Objectives:

The Sawing Machine Operator adjusts saw blades, using wrenches and rulers, or by turning hand wheels or pressing pedals, levers, or panel buttons. The Sawing Machine Operator inspects and measures work pieces to mark for cuts and to verify the accuracy of cuts, using rulers, squares, or caliper rules. The Sawing Machine Operator examines logs or lumber in order to plan the best cuts. The Sawing Machine Operator sets up, operates, or tends saws and machines that cut or trim wood to specified dimensions, such as circular saws, band saws, multiple-blade sawing machines, scroll saws, ripsaws, and crozer machines. The Sawing Machine Operator inspects stock for imperfections and to estimate grades or qualities of stock or work pieces.

The Sawing Machine Operator must operate panel boards of saw and conveyor systems to move stock through processes, and to cut stock to specified dimensions. The Sawing Machine Operator mounts and bolts sawing blades or attachments to machine shafts. The Sawing Machine Operator must monitor sawing machines, adjust speed and tension and clear jams to ensure proper operation. The Sawing Machine Operator selects saw blades, types and grades of stock, and cutting procedures to be used, according to work orders or supervisors’ instructions. The Sawing Machine Operator guides work pieces against saws, saw over work pieces by hand, or operate automatic feeding devices to guide cuts. The Sawing Machine Operator needs knowledge of machines and tools, including their designs, uses, repair, and maintenance. They also must have knowledge of raw materials, production processes, quality control, costs, and other techniques for maximizing the effective manufacture and distribution of goods. The Sawing Machine Operator must have a relative good knowledge of arithmetic, algebra, geometry, calculus, statistics, and their applications.

Machine Shop Saw Operationthe Mechanic

Activities:

The Sawing Machine Operator uses either control mechanisms or direct physical activities to operate machines or processes not including computers or vehicles. The Sawing Machine Operator uses hands and arms in handling, installing, positioning, and moving materials and manipulating things. The Sawing Machine Operator inspects equipment, structures, or materials to identify the cause of errors or others problems or defects. The Sawing Machine Operator is expected to perform physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling of materials. The Sawing Machine Operator observes, receives, and otherwise obtains information from all relevant sources. The Sawing Machine Operator must be able to identify information by categorizing, estimating, recognizing differences or similarities, and detecting changes in circumstances or events. The Sawing Machine Operator monitors and reviews information from materials, events, or the environment, to detect or assess problems. The Sawing Machine Operator must provide information to supervisors, co-workers, and subordinates by telephone, in written form, e-mail, or in person. The Sawing Machine operator estimates sizes, distances, and quantities; or determining time, costs, resources, or materials needed to perform a work activity. It is important that they assess the value, importance or quality of things or people before accepting the job.

Abilities:

The Sawing Machine Operator needs the ability to keep the hand and arm steady while moving the arm or while holding the arm and hand in one position as they are doing their job performance. The Sawing Machine Operator needs the ability to quickly and repeatedly adjust the controls of a machine or a vehicle to exact positions. The Sawing Machine Operator needs the ability to see details at a very close range. They need to be able to make precisely coordinated movements of the fingers of one or both hands to grasp, manipulate, or assemble very small objects. The Sawing Machine Operator needs the ability to listen to and understand information and ideas in speaking so others will understand. The Sawing Machine Operator to listen to and understand information and ideas presented through spoken words and sentences. The Sawing Machine Operator needs the ability to tell when something is wrong or is likely to go wrong. It does not involve solving the problem, only recognizing there is a problem. The Sawing Machine Operator needs the ability to use your abdominal and lower back muscles to support part of the body repeated or continuously over time with giving out or fatiguing.

Machine Shop Saw Operation The Mechanical

Leave a Comment

Do You Work as a Sawing Machine Operator ?

Machine Shop Saw Operation The Mechanic Shop

Tell us about your experience as a Sawing Machine Operator . How much you earned, who your employer was, how much education was required or anything that pertains to this career. Help others who are trying to enter into this field. All information is kept anonymous.